Product Description

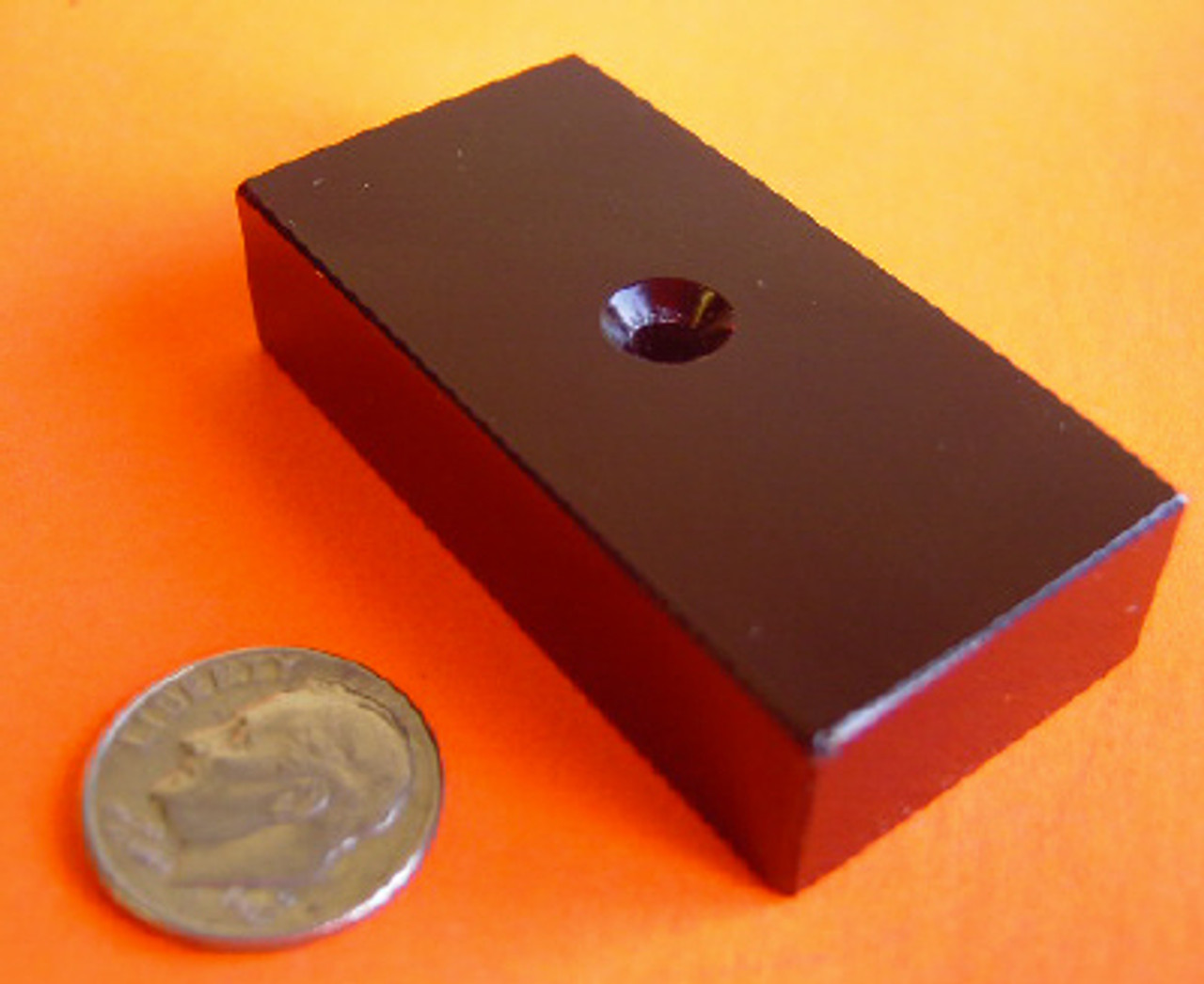

N52 Magnets 2 in x 1 in x 1/2 in w/Dual Side CounterSunk Hole Epoxy

N52 Magnets 2" x 1" x 0.5" Thick Neodymium NdFeB Block Rare Earth Magnet with tapered countersunk hole

Extremely durable Epoxy + Copper + Nickel Triple Layer Coated with tapered center hole

Tapered counter sunk center hole on both sides of magnet to recess a screw head

0.17" Diameter counter sunk center hole fits with #8 metal screws

N52 Magnets - Neodymium Rare Earth Magnets, used for building more efficient wind generators in Hugh Piggott's "How to Build Wind Turbine" book

Epoxy-Nickel-Copper-Nickel triple layer coated for maximum N52 magnets protection and durability

| YOU GET WHAT YOU PAY FOR !!! For wind generator magnets, coating and performance are the most important things to consider, we recommend Nickel+Copper+Nickel 3-layer coating for long term durability under all weather conditions, we don't recommend Epoxy single layer coating, please read details below. To have better performance for your wind generator, the higher grade the magnets, the better; N52 grade offers better performance than N50, N48, N45, N42, N38 and N35. |

Grade Makes a big difference ! The higher the grade, the stronger the Rare Earth Magnets

N52 is stronger than N50, N48, N45, N42, N40, N38 and N35

Coating Makes a big difference !

Hugh Piggott talks about wind turbine failure caused by magnet corrosion due to bad coating in his book:

"........ the magnets themselves that can lead to a major failure in under 5 years............. Once the protective plating on the magnet is punctured, the magnet corrodes and swells gradually."

3-layer coating (Nickel + Copper + Nickel and Epoxy + Copper + Nickel) vs. Epoxy single layer coating

Epoxy single layer coating is THE LEAST durable coating from our experience.

3-layer coating is much more durable than Epoxy single layer coating because Epoxy single layer coating is a thin layer of plastic and quicker to wear off, even a scratch can damage the coating easily.

More importantly, magnets with 3-layer coating have superior cracking and chipping resistance in comparison to magnets with Epoxy single layer coating. Customer beware of the magnets with the inferior Epoxy single layer coating.

Epoxy+Copper+Nickel 3-layer coating vs. Nickel+Copper+Nickel 3-layer coating

Epoxy + Copper + Nickel 3-layer coating has superior Corrosion Resistance and excellent adhesion to metal surface than Nickel + Copper + Nickel coating, this coating is ideal for bonding metal. Nickel+Copper+Nickel coating provides protection against moisture and oxygen but is prone to corrosion in salt and acidic conditions.

Magnetized through the Thickness 0.5", poles are on the two 2x1" surfaces

Neodymium rare earth magnets are the world's strongest magnets. All magnets are not created equal! Applied Magnets offers the highest quality magnets with consistent performance at lowest price. Our strong magnets are designed & manufactured to meet stringent quality standards using the latest technology.

neodymium magnets (also known as Neo, NdFeB, NIB or super magnets), a type of rare earth magnets, are the permanent magnet made from neodymium, iron, boron and other minor elements.

Super strong neodymium rare earth N52 magnets, stronger than N50, N48, N45, N42, N40, N38 and N35

BrMax: 14800 gauss

Approximate pull force: 92 lbs

ISO certified strong neodymium rare earth magnets with the best corrosion-resistant coating of Epoxy + Copper + Nickel.

Contact us for neodymium rare earth N50 magnets wholesale discount.